|

| Site Partners: | SpotterGuides | Veloce Books |

| Related Sites: | Classic Cars Monthly | Your Link Here |

|

|||||||||||

|

|||||||||||

|

|

#1 | ||

|

Ten-Tenths Hall of Fame

Veteran

Join Date: Sep 2008

Posts: 14,830

|

Driveline Alignment live-axle RWD cars

I suppose this thread could be somewhere else but my guess is most of the knowledge is here! And as my contribution to rejuvenating HRT, I expect it to attract as much response as other recent threads...

Story is, I had the rear springs de-cambered for the Gp1 Escort and looking at the diff nose am thinking that it is not in line with crank / gearbox output anymore. I've now got a spirit level App on phone so can check tomorrow. Questions- What sort of tolerance is there on angle, and if I decide to have a play, are wedges available off the shelf? I've seen 4+4 specialists (in USA most) touting them, but not any race part suppliers.

|

||

|

|

__________________

Logic will get you from A to B. Imagination will take you everywhere. (Einstein)

|

|

|

#2 | ||

|

Racer

Join Date: Mar 2009

Posts: 340

|

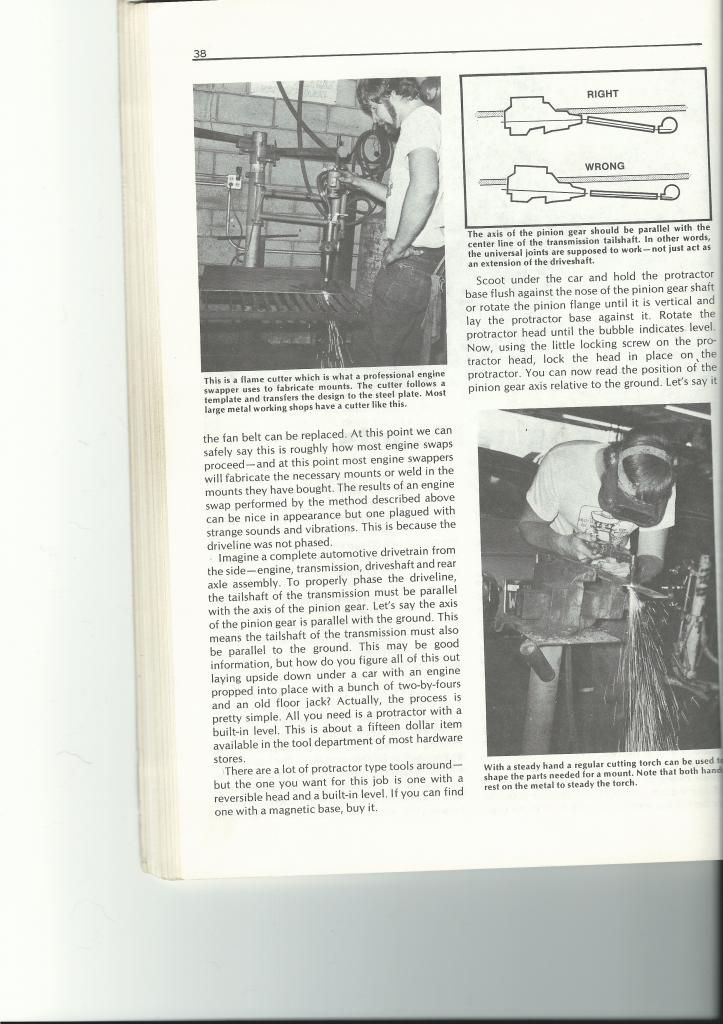

Are you talking drive line phasing? On a live axle car it is a little more complicated in that the diff nose can move up and down with the torque rotation of the leafs….Set up will all depend on how axle is suspended..

With a fixed diff the set up is to ensure that the angles add up to 180 degrees. I use an old rabone magnetic angle setter to check..The relative height of engine and diff isn't critical but both sets of prop joints should be in phase IE the corresponding angles adding up to 180.. so if your diff nose points upward by say 4 degrees (274 degrees) then the gearbox nose should point downward by 4 degrees..(94 degrees) 274 - 94 = 180. As alluded to on live axles the nose can rotate under engine torque, from memory 2-3 degrees was allowed for to ensure alignment under constant power…. There is also an optimum angle for the U/J's to operate under. so you should never angle engine down and diff up to allow non operation of the U/J. I think 8 - 10 degrees is usually about right but I would google optimum u/j angles My old friend is still fords GP 4 works prep manual which tells you to weld washers on the leaf pins and throw away isopack mounting rubbers etc. This is an extract from Practical engine swapping...  N. Last edited by Heightswitch; 1 Mar 2015 at 17:58. |

||

|

|

|

|

|

#3 | ||

|

Veteran

Join Date: Nov 2006

Posts: 9,412

|

We always angled the diff nose down, as the pinion effectively tries to climb round the crown wheel under acceleration it causes axle tramp because of the leaf springs winding up and releasing, if it's angled down for a start the leverage angle is actually going towards a lesser angle.

|

||

|

|

__________________

Balls of steel (knob of butter) They're Asking For Larkins. ( Proper beer) not you're Eurofizz crap. Hace más calor en España. Me han conocido a hablar un montón cojones! Send any cheques and cash to PO box 1 Lagos Nigeria Africa !

|

|

|

#4 | ||

|

Ten-Tenths Hall of Fame

Veteran

Join Date: Sep 2008

Posts: 14,830

|

That was quick and informed! Cheers.

Yes, it's getting the u/j at both ends of prop working in phase I am concerned about. Axle 'wind up' shouldn't be too much as car has two radius arms going to top of casing or anti roll bar that achieves a similar result. The axle has uniform lowering blocks that are bolted to spring and a machined fit into saddle, but diff nose looks to naked eye to be pointing down, while the engine and gearbox are also slightly 'downhill' to the rear of car. To me and your diagrams that's wrong, and diff nose angle needs to be closer to that of the crank / gearbox shafts. I've seem wedges used to achieve this, but looks like will have to make from scratch, or maybe have some lowering blocks machined down. Question is, how big an angle...... Gordon, thanks also. It may be that angle is correct using your theory.

|

||

|

|

__________________

Logic will get you from A to B. Imagination will take you everywhere. (Einstein)

|

|

|

#5 | ||

|

Racer

Join Date: Mar 2009

Posts: 340

|

Lift your gearbox and add some spacers if it is only a matter of a couple of degrees? or are you too tight to tunnel for clearance. As Gordon alluded too if you are looking at 178 - 9 degrees with nose of diff angled v slightly downward then you won't be too far away. Ideally then your gearbox should be level and your joints working at a good angle (dependant of course on relative heights of your gearbox - diff. if you are confident that your radius arms will prevent axle rotation then stick with 180 degrees static I would think even on an original isopacked set up any downward attitude of the diff would only be a couple of degrees.

I would measure the angles first and see how far out you are. given a choice, dropping engine and box or altering its attitude will generally be easier than buggering about shimming up a diff You mentioned machined blocks?? Are they correct way round? just a thought. N. Last edited by Heightswitch; 1 Mar 2015 at 19:26. |

||

|

|

|

|

|

#6 | ||

|

Veteran

Join Date: Feb 2010

Posts: 826

|

|||

|

|

__________________

"Light travels faster than sound - that's why, at first, some people appear bright... until you hear them speak!"

|

|

|

#7 | |

|

Veteran

Join Date: Mar 2013

Posts: 966

|

Not sure how to post the paper on here , so have sent tech paperwork on propshaft alignment to your Email Mike .

|

|

|

|

|

|

|

#8 | ||

|

Ten-Tenths Hall of Fame

Veteran

Join Date: Sep 2008

Posts: 14,830

|

Thanks Tel, good info again.

Paul, I feared that HRT would stand for something else, and that some bright spark would know......  Heighty, not possible to raise gearbox as tunnel metal too close. Will measure angles later today and post some figures.....

|

||

|

|

__________________

Logic will get you from A to B. Imagination will take you everywhere. (Einstein)

|

|

|

#9 | ||

|

Veteran

Join Date: Oct 2005

Posts: 1,272

|

This Youtube video illustrates propshaft angle and phasing very well.

https://www.youtube.com/watch?v=Idk3BVDVHq4 |

||

|

|

|

|

|

#10 | ||

|

Subscriber

Veteran

Join Date: Oct 2007

Posts: 8,715

|

This sure is interesting . Stuff I have never even thought about. Apart from making sure new prop shafts we have made are the correct length and UJ 'a lined up and prop is balanced. Trouble is have you ever looked at some of the FJ cars and the set ups on them

|

||

|

|

|

|

|

#11 | |||

|

Veteran

Join Date: Nov 2006

Posts: 9,412

|

Quote:

In days of old when I was adapting a propshaft (with different flanges or shortening) I used to balance it on the actual car while it was on a wheel free ramp. I would get someone to drive it in top gear and hold a piece of chalk close to the shaft so that it would make a mark and then fit pieces of sheet metal on the opposite side with jubilee clips until I had a uniform circle all the way round. Very technical but it worked

|

|||

|

|

__________________

Balls of steel (knob of butter) They're Asking For Larkins. ( Proper beer) not you're Eurofizz crap. Hace más calor en España. Me han conocido a hablar un montón cojones! Send any cheques and cash to PO box 1 Lagos Nigeria Africa !

|

|

|

#12 | |||

|

Subscriber

Veteran

Join Date: Oct 2007

Posts: 8,715

|

Quote:

|

|||

|

|

|

|

|

#13 | |

|

Veteran

Join Date: Apr 2002

Posts: 9,710

|

Interesting stuff . . . . I'm off down the workshop to have a look at my car now!

|

|

|

|

|

|

|

#14 | |||

|

Ten-Tenths Hall of Fame

Veteran

Join Date: Sep 2008

Posts: 14,830

|

Quote:

The concern I have about my car is to do with the angles at either end of prop not being equal. I've crudely measured at normal ride height thus- Engine /crank / gearbox angled DOWN towards rear of car 3.25 degrees. Propshaft angled DOWN towards rear of car 2.0 degrees. Diff pinion line angled UP towards rear of car 3.25 degrees. In my book that means a mis-alignment between front and rear of 6.5 degrees, which am sure is not good for diff or gearbox! Granted there could be a change for the better during acceleration if 'wind up' occurs, and perhaps when cornering it could improve, but still sounds too much to me.... I remember looking under the back of a Gp1 CTCRC car using same axle and single leaf springs, and noticing that the latter were 'S' shaped, which could have been in order to lift the diff nose....

|

|||

|

|

__________________

Logic will get you from A to B. Imagination will take you everywhere. (Einstein)

|

|

|

#15 | |||

|

Racer

Join Date: Mar 2009

Posts: 340

|

Quote:

N. |

|||

|

|

|

|

|

#16 | ||

|

Veteran

Join Date: Apr 2004

Posts: 3,810

|

I read '...Diff pinion line angled UP towards rear'

|

||

|

|

__________________

a salary slave no more...

|

|

|

#17 | ||

|

Ten-Tenths Hall of Fame

Veteran

Join Date: Sep 2008

Posts: 14,830

|

Sorry if it isn't written very clear, but David has it right....

|

||

|

|

__________________

Logic will get you from A to B. Imagination will take you everywhere. (Einstein)

|

|

|

#18 | ||

|

Racer

Join Date: Mar 2009

Posts: 340

|

Ah..Well in that case it is ****ed.

If you are 2 degrees on prop angle then I would be lowering engine and lifting gearbox to lessen the out of phase, This will have the benefit of increasing the prop and hence yoke angles to a more desirable angle. It sounds to me that Maybe an engine transplant has thrown some of the driveline out of whack with the diff. Are your top radius arms adjustable? If so I would wind them about to see how much flex you have in the diff movement. I am assuming you are still using std leafs and a fairly standard set up at the rear? If it was my car I would be sorting engine and box first then tweaking diff to a suitable phased drive line whilst increasing the prop yoke angles slightly. Heres a better article which looks like it was lifted from my book. http://jniolon.clubfte.com/driveline...nephasing.html N. |

||

|

|

|

|

|

#19 | ||

|

Ten-Tenths Hall of Fame

Veteran

Join Date: Sep 2008

Posts: 14,830

|

Thanks again, but we are talking of a Gp1 car here, with standard production engine and gearbox position. Squeezing a Pinto into an Escort resulted in some 'angling' in two dimensions being required! (Although not as bad as a Twin Cam, RS1600 or Mexico where the engine was angled even more from centre line to give carb clearance!)

Any mods are going to have to be at rear, as it is the springs that have been alterered to lower the car. Either shims under saddles or re-shaping springs would work. Radius arms if I have them fitted are non adjustable, but the alternative ARB ends thread on, so it is. Out of interest I will unbolt it from axle and see if it changes anything! Frustratingly, the shims mentioned are freely available (in various degrees of angle) in the USA as widely used on lifted 4x4s. Will have to check if any UK specialists stock them, but are keeping quiet about it. If not will be chatting up a machinist........ |

||

|

|

__________________

Logic will get you from A to B. Imagination will take you everywhere. (Einstein)

|

|

|

#20 | |||

|

Racer

Join Date: Mar 2009

Posts: 340

|

Quote:

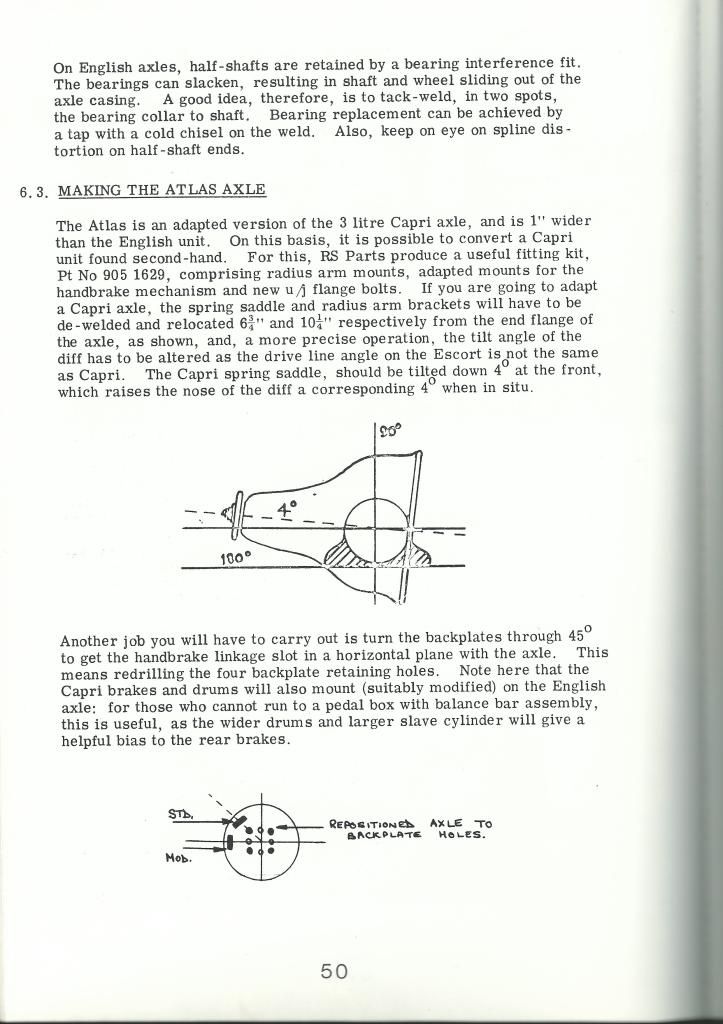

I will dig out my old ford book and see if it says anything?? The boreham book shows the diff flange pointing 4 degrees upward towards the gearbox on a 4 linked rear end.  This shows what an atlas in an escort should be set up like. I don't know if you have an english or have switched to an atlas but the section on re welding the spring saddle and radius arm brackets is interesting. N. N. Last edited by Heightswitch; 2 Mar 2015 at 21:31. |

|||

|

|

|

|

|

#21 | ||

|

Ten-Tenths Hall of Fame

Veteran

Join Date: Sep 2008

Posts: 14,830

|

I cannot lift the box or lower the engine, even if wanted to! Any adjustment will be at the rear, where will have less effect on anything else and there is room to play with.

Am thinking modified spring spacer (lowering) blocks, machined to an angle. Simple and quick to swap- could have two or three sets made with different angles......

|

||

|

|

__________________

Logic will get you from A to B. Imagination will take you everywhere. (Einstein)

|

|

|

#22 | |

|

Veteran

Join Date: Mar 2013

Posts: 966

|

A few thoughts on this one .

We have always considered the original Ford Rally Prep manual wrong with the upward angle on the diff , [ confirmed by Gartrac & others ] , & have always tried to mount the diff so that the pinion shaft has the same alignment as the gearbox shaft . This should mean that the propshaft has the same [ but reversed ] angles on each end . A very rough calculation gives 1 degree alteration on engine / gearbox angle as about half an inch up or down at either mounting , so if that is not very easy to get , then the diff will have to be twisted . If your diff is up at the rear [ down at the front ] then it does sound like you probably need a fair bit of adjustment . This could also mean that you might have to lengthen your top radius arms [ assuming Gp 1 type ] . It might need cutting & welding the axle to spring brackets to get that much movement . A personal view is that it is worth doing as running odd angles on the U/Js could give some snatch on the transmission which would lead to reduced traction , as well as harshness & wear on components . |

|

|

|

|

|

|

#23 | ||

|

Ten-Tenths Hall of Fame

Veteran

Join Date: Sep 2008

Posts: 14,830

|

I'm on the case, Tel, thanks. My belief is that the way springs have been de-cambered has introduced the error. As I mentioned earlier, have seen a similar set up where springs (single leaf BTW) have had a slight S bend introduced, which allows the axle to mount at a better angle. I'm machining some lowering blocks to an appropriate angle to correct the error. As am running ARB rather than standard radius arms (both homologated!) the ends are adjustable, so can take out any location issue with that.

|

||

|

|

__________________

Logic will get you from A to B. Imagination will take you everywhere. (Einstein)

|

|

|

#24 | ||

|

Ten-Tenths Hall of Fame

Veteran

Join Date: Sep 2008

Posts: 14,830

|

The simple solution, lowering blocks milled at appropriate angle...

|

||

|

|

__________________

Logic will get you from A to B. Imagination will take you everywhere. (Einstein)

|

|

|

#25 | ||

|

Racer

Join Date: Mar 2009

Posts: 340

|

|||

|

|

|

|

|

|

Similar Threads

Similar Threads

|

||||

| Thread | Thread Starter | Forum | Replies | Last Post |

| Why are ERC 1600cc and 2000cc cars separated by FWD and RWD? | Greg Cozier | Rallying & Rallycross | 8 | 16 May 2013 16:55 |

| Fully locked diffs in RWD front engined live axled cars. | Al Weyman | Racing Technology | 43 | 19 Nov 2008 00:03 |

| Fully locked diffs in RWD front engined live axled cars. | Al Weyman | Racing Technology | 10 | 17 Aug 2008 11:18 |

| FIA Increase Weight of Sequential RWD Cars | Wilbo | Touring Car Racing | 11 | 10 Nov 2007 18:46 |

| Minus 15 kilos for RWD cars in WTCC | JMeissner | Touring Car Racing | 4 | 10 Mar 2007 10:30 |